Table of Contents

Introduction: R290 for Modern Heat Pumps

R290 (propane) delivers excellent thermodynamic efficiency.

Therefore, installers and dealers increasingly specify it for compact heat pumps.

However, R290 is flammable, so technicians must respect safety rules.

Accordingly, leak detection and proper procedures make R290 practical and safe.

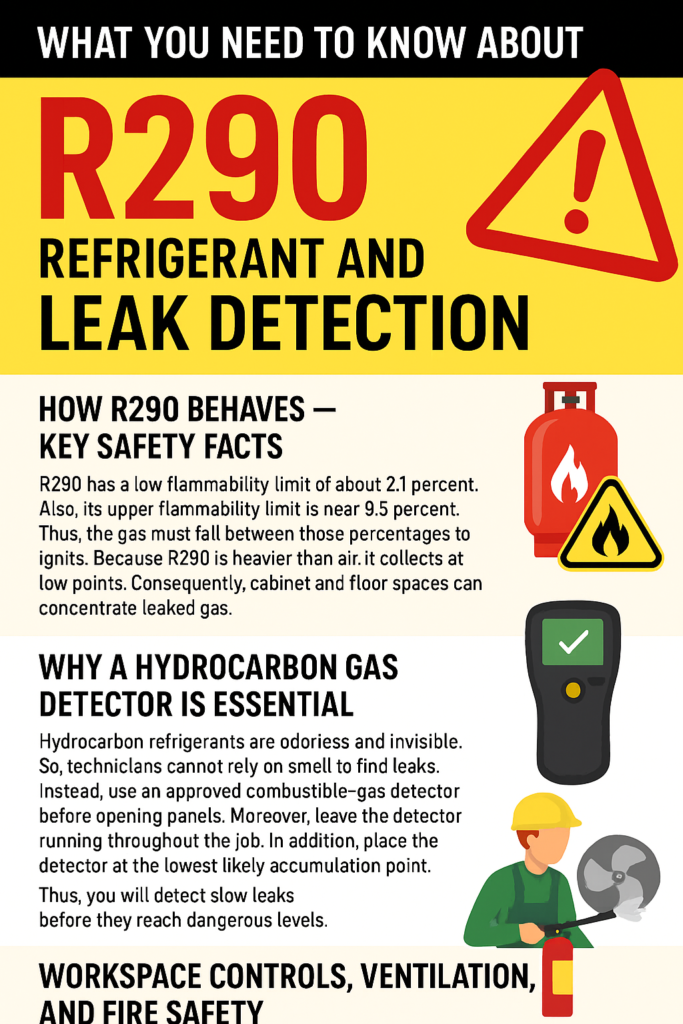

How R290 Behaves — Key Safety Facts

R290 has a low flammability limit of about 2.1 percent.

Also, its upper flammability limit is near 9.5 percent.

Thus, the gas must fall between those percentages to ignite.

Because R290 is heavier than air, it collects at low points.

Consequently, cabinet and floor spaces can concentrate leaked gas.

Therefore, always ventilate and monitor low areas first.

Why a Hydrocarbon Gas Detector Is Essential

Hydrocarbon refrigerants are odorless and invisible.

So, technicians cannot rely on smell to find leaks.

Instead, use an approved combustible-gas detector before opening panels.

Moreover, leave the detector running throughout the job.

In addition, place the detector at the lowest likely accumulation point.

Thus, you will detect slow leaks before they reach dangerous levels.

Workspace Controls, Ventilation, and Fire Safety

First, perform a formal risk assessment for each site.

Next, clear at least a ten-foot radius around the unit.

Also, remove or isolate any potential ignition sources.

Furthermore, post visible “Flammable Refrigerant” warning placards.

Keep an R290-proof fan or remote fan ready for emergency ventilation.

Finally, keep a dry-powder fire extinguisher on site at all times.

Tools, Recovery Equipment, and Electrical Parts

Only use tools and gauges rated for hydrocarbons.

Also, use vacuum pumps and recovery units approved for R290.

Moreover, use the correct recovery cylinder designed for hydrocarbons.

Always use IEC-approved electrical parts that are non-spark producing.

Otherwise, a relay or switch might ignite leaked gas.

Thus, replace suspect parts with OEM or certified aftermarket items.

System Diagnostics and Common Failure Causes

Compressor failure rarely occurs by itself.

Instead, system faults often cause compressor damage.

Therefore, conduct a full system diagnosis before replacing compressors.

Check for restricted airflow, blocked heat exchangers, and incorrect charge.

Also, inspect electrical controls and refrigerant lines for damage.

Consequently, you will avoid unnecessary compressor swapouts and repeat visits.

Service Workflow: Step-by-Step Best Practices

First, sweep the outside cabinet with a gas detector.

Then, scan the inside of the cabinet before opening.

Next, isolate power and lock out electrical sources.

After that, ventilate and keep the detector running.

Finally, only re-energize once the workspace reads safe on the detector.

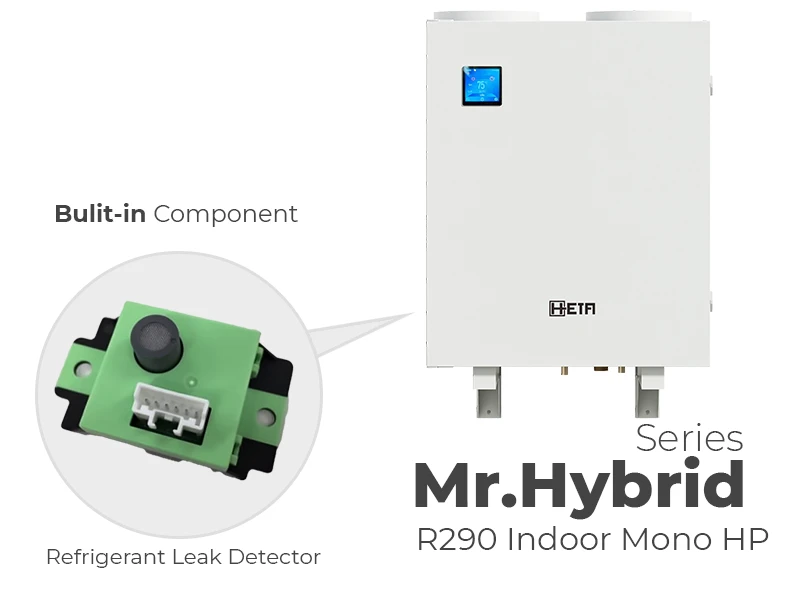

Product Spotlight: Mr. Hybrid — Built-in Leak Detection

Hetapro’s Mr. Hybrid is a compact, wall-mounted indoor R290 heat pump.

Notably, Mr. Hybrid includes a built-in Refrigerant Leak Detector as standard.

Therefore, installers get continuous, integrated leak monitoring from day one.

Also, Mr. Hybrid uses a small refrigerant charge and sealed components.

Thus, it simplifies service while maintaining high efficiency and safety.

Installers will appreciate fewer compliance steps and easier commissioning.

Product Option: Heatix Monobloc — Optional Leak Detector

Hetapro’s Heatix R290 monobloc air-to-water heat pump installs outdoors.

Importantly, Heatix can be ordered with an optional Refrigerant Leak Detector.

Consequently, technicians can tailor monitoring to site demands.

Also, outdoor placement reduces indoor accumulation risk.

However, optional detection still improves safety and early fault finding.

Regulatory and Practical Benefits

R290 has ultra-low GWP and no ozone-depleting potential.

Therefore, it supports sustainability goals and reduces carbon impact.

Also, modern low-charge designs lower installation complexity.

Nevertheless, compliance requires training, correct parts, and leak detection.

Hence, investing in detectors and certified tools protects people and property.

Conclusion: Practical Steps for Safe R290 Service

Always assume a flammable refrigerant until proven otherwise.

Next, use an approved gas detector, ventilate, and isolate power.

Moreover, use R290-rated tools and IEC-approved electrical parts.

Finally, choose equipment with built-in detection when possible.

For instance, Mr. Hybrid includes an integrated leak detector as standard.

Meanwhile, the Heatix monobloc offers leak detection as an option.

Thus, with training and the right gear, R290 systems are safe and efficient.

Frequently Asked Questions (FAQ)

Q1 — Is R290 safe for indoor heat pumps?

Yes. When installed per manufacturer guidance, with low refrigerant charge and leak detection, R290 is safe.

Q2 — Do I need an F-Gas certificate to install or service R290 units?

Generally no for propane systems, but local rules vary. Always confirm national regulations before work.

Q3 — Why is a Refrigerant Leak Detector essential?

R290 is odorless and heavier than air. Detectors find leaks early and prevent dangerous concentration.

Q4 — Where should I place the gas detector during service?

Place it low inside the cabinet and on the ground in front of the worksite. Keep it running throughout the job.

Q5 — How often should I test or calibrate detectors?

Check detectors before every job. Calibrate or service them per the manufacturer schedule.

Q6 — Can I use my existing recovery pump and cylinders?

Only if they are certified for hydrocarbons. Otherwise use R290-rated recovery machines and approved cylinders.

Q7 — What personal protective equipment and tools are required?

Use anti-static gloves, eye protection, IEC-approved non-sparking tools, and spark-proof gauges when working with R290.

Q8 — What if I find a leak during service?

Stop work, ventilate the area, evacuate non-essential staff, post warnings, and repair with approved parts. Verify safety with the detector before re-energizing.

Q9 — Does Hetapro offer built-in leak detection?

Yes. The Mr. Hybrid indoor wall-mounted R290 heat pump includes a built-in Refrigerant Leak Detector as standard. The outdoor Heatix monobloc offers leak detection as an optional accessory.